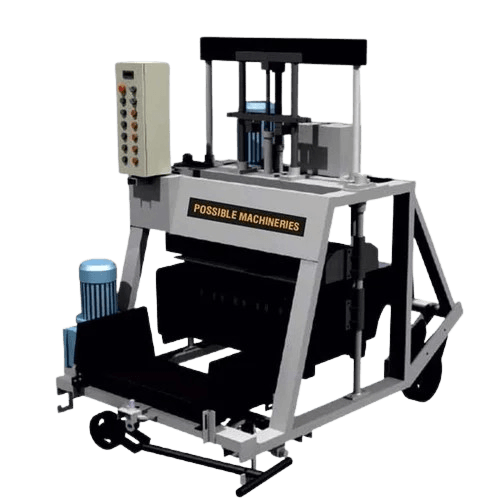

Egg Laying Block Making Plant

₹460,200.00

The Egg Laying Block Making Plant is a mobile, semi-automatic machine designed for on-site production of concrete blocks. It efficiently produces high-quality hollow, solid, and paver blocks with minimal labor and operational costs. Ideal for small to medium-scale construction projects, this plant ensures durability, ease of use, and high output capacity.

Description

| Capacity | 2500 Per/Shift |

| Brand | Possible Machineries |

| Warranty | 1 Year |

| Material | Mild Steel |

| Country of Origin | Made in India |

| Block Type | Egg Laying |

| Automation Grade | Semi Automatic |

| Method | Hydraulic Pressure |

| Usage/Application | Industrial |

The Egg Laying Block Making Machine is able to produce the various hydro vibro block in one machine with premium quality.

Mould Area: 870X400mm

Vibrations: 6000 Hz Amplitude Adjustable

Drive: 25:1 worm reduction gear box and chain through front wheel

Production Capacity: Hollow and Solid Blocks

60 to 70 strokes/hr:

300X200X100MM Blocks-450 To 500/hr

300X200X150MM Blocks-270 To 320/hr

300X200X200MM Blocks-220 To 260/hr

Travelling Motor: 0.5hp

Vibrator Motor: 1.5hp

Hydraulic Pump Motor: 3 hp

Weight: 1500kg0

An egg-laying block making plant is a type of concrete block-making machine that produces blocks without requiring a stationary mold or pallet. The machine moves forward while laying the blocks on the ground, similar to how a chicken lays eggs—hence the name “egg-laying.”

Features & Benefits

- Mobility – The machine is designed to move, allowing for on-site production.

- No Need for Pallets – Blocks are laid directly on the curing surface.

- Cost-Effective – Reduces operational costs since no pallets are needed.

- High Efficiency – Capable of producing a large number of blocks in a single run.

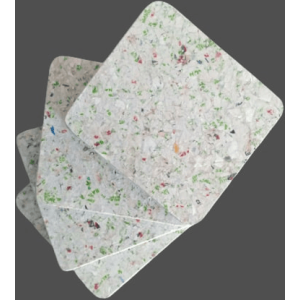

- Variety of Block Types – Can produce solid, hollow, and interlocking blocks.

Types of Egg Laying Block Machines

- Manual – Operated by hand with limited output.

- Semi-Automatic – Some mechanized functions but requires manual input.

- Fully Automatic – Uses hydraulics and automation for high production.

How It Works

- Raw Material Mixing – Cement, sand, aggregates, and water are mixed.

- Feeding into the Machine – The mixture is loaded into the block-making machine.

- Compression & Molding – The machine compresses and shapes the blocks.

- Block Laying – The machine moves forward while laying freshly molded blocks on the ground.

- Curing – Blocks are left to dry and cure before being used in construction.

Applications

- Residential and commercial buildings

- Roadside paving

- Compound walls

- Infrastructure projects

Reviews

There are no reviews yet.