Plastic Paver Block Pallet

₹80.00

As demand for sustainable, high-durability construction materials rises, plastic paver block pallets are becoming the preferred choice for modern block manufacturers. Possible Machineries offers a one-stop solution – from advanced production lines to pallet customization – empowering industries to build smarter, stronger, and more sustainably.

Description

Plastic Paver Block Pallet Manufacturing by Possible Machineries

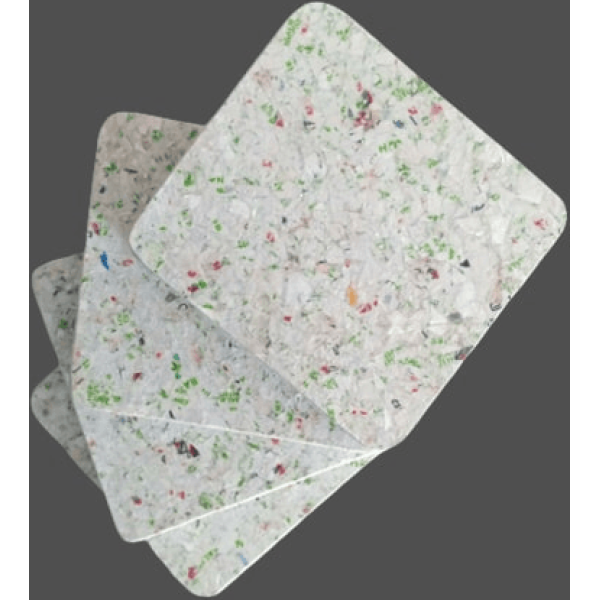

We are manufacturer and supplier of Recycled Plastic Paver Block Pallet. Our offered Recycled Plastic Paver Block Pallets are best substitute of conventional wood, plywood and metal pallets. Our pallets are suitable for all machine types such as automatic, semi-automatic and manual that used for manufacturing bricks and blocks. Our pallets are ideal to stack moulds of all sizes and shapes. Our Recycled Plastic Pallets are long lasting and cost effective for palletisation of bricks and blocks. Further our offered products are tested on various parameter of quality in order to deliver flawless range at the client’s end.

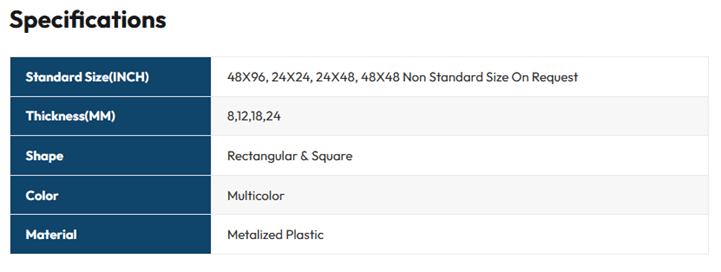

Sizes Available – 8\12\18\24 mm

Plastic paver block pallets are an essential component in the modern block manufacturing process, providing a durable, reusable platform for molding, curing, and transporting paver blocks. At the forefront of this industrial evolution is Possible Machineries, a leading manufacturer based in MIDC Ambad, Nashik, known for delivering robust and innovative machinery solutions tailored to the block and tile production industry.

🧱 What Are Plastic Paver Block Pallets?

Plastic paver block pallets are sturdy, waterproof, and reusable platforms made from recycled plastic or polymer composites. They are used as a base for shaping concrete or plastic-based paver blocks in vibrating tables or hydraulic presses. Unlike traditional wooden or metal pallets, plastic pallets:

Resist moisture, decay, and chemical damage

Are lightweight yet durable

Offer a smooth surface finish for block shaping

Provide long-term cost savings due to extended life cycles

🛠️ Machinery Used in Plastic Paver Block Pallet Manufacturing

1. M-50 Grade Fully Automatic Paver Block Plant

Equipped with automated batching, feeding, and hydraulic pressing systems

Supports high-volume production (up to 14,000 blocks per shift)

Compatible with heavy-duty plastic or PAC (Plastic Aluminium Composite) pallets

Ideal for industrial-scale manufacturing using thermoplastic or concrete mixtures

2. Hydraulic Interlocking Block Making Machine

Delivers up to 5,000 blocks per shift

Designed for producing precision interlocking plastic or composite blocks

Integrated with high-pressure hydraulic force (up to 50 tons) to ensure dense, dimensionally accurate output

3. Vibration Table Paver Block Machine

Manual or semi-automatic configurations

Used for forming plastic paver blocks using high-frequency vibration

Suitable for small-scale operations or startups

4. Custom Mold Integration for Plastic Processing

Machines are adapted to support heat-resistant plastic pallets

Mold cavities are customized to handle plastic polymer or composite blends

Allows the production of designer pavers, interlocking tiles, and load-bearing blocks

🔧 Plastic Pallet Customization & Support

Possible Machineries partners with local plastic recyclers and pallet fabricators to provide custom pallet solutions. These pallets are:

Designed to handle loads of up to 200 tons

Heat- and UV-resistant, ideal for outdoor curing

Available in various sizes (up to 900×600 mm, 25 mm thick)

Molded to match any paver block machine in their product line

🌱 Sustainability Advantage

By promoting the use of recycled plastic materials, Possible Machineries supports eco-friendly manufacturing practices. Their technology allows the integration of shredded plastic waste into block manufacturing – contributing to a circular economy in construction.

Additional information

| Length | Per Centimeter |

|---|

Reviews

There are no reviews yet.